Rolls-Royce Modern Car Restoration 2008

As our fame spread to the four corners of the globe, this car came to us all the way from Majorca for our modern car restoration services.

"The motor from Majorca don't look like what it oughta!"

Intro

We got a call from a gentleman who asked us if we could work on his Rolls-Royce Silver Seraph. He had been looking for somebody to Connollise his leather and saw that we also refurbished wheels, removed dents and a few other things by reading our website, so he decided to call us. We looked at the photos he sent by email, told him we could do most of them, and he seemed eager to book his car in with us. As it transpired, the car was in Majorca. We are quite prepared to collect cars from just about anywhere, but in this case, the customer shipped the car to Ramsgate, and we had it collected from there.

The car arrived here from Ramsgate minus the Walnut tops of the doors which had been removed and sent direct to Cooper Woodtrim who specialize in Rolls-Royce and Jaguar interior wood restoration.

I have to say, they did a fantastic job on them, and without a doubt, we will be recommending them to our customers in future. They did come back darker than the rest of the walnut, but that is to be expected, as the rest of the walnut will have faded over the years. The customer was also suitably impressed and vowed to have the rest of the walnut done next time.

We were only given a short time to work on the car, it was here for about 10 days, and unfortunately a bank holiday weekend fell within this period. We were also slightly hindered by the fact that some of our technicians were away on holiday, but we did get done everything that was promised, except for the smart repairs because upon inspecting the car, we felt this method of repair wouldn't be adequate. The car will be coming back to us later this year when we will complete phase two, which will include bodywork and paintwork correction.

Wheel Refurbishment

All the wheels were scuffed, and the photo right, shows how the raised detail was badly damaged. This required some reconstruction, which was rather difficult to do. It needed to be built up again and then re-shaped, which is much easier said than done.

Our normal process for refurbishing wheels is to take the wheel off, deflate the tyres, and then use a special machine for 'breaking the bead', which means pushing the tyre back from the front edge.

This exposes the rim allowing it to be worked on properly, it also allows the tyre to be masked out properly and more easily. Any gouges can then be filled with metal filler, there is no need for welding as we do not undertake work where the rim is so badly damaged that it has compromised the structural integrity. The filler just repairs cosmetic damage, even so a special liquid metal filler is used. Next, the whole face of the wheel is then rubbed down and repainted with primer, base coat and clear coat (lacquer).

The white wall tyres did have us wondering. There was a time when they were fairly common and most suppliers of valeting products would have had both a tyre blacking and a white rubber paint. But these days, nobody uses 'tyre black' instead we use clear dressings that feed and protect the rubber. And we really didn't want to get into the business of painting the white walls even if the paint was available! Luckily, we were able to clean off any dirty marks, and once dressed with a normal dressing they looked like new.

Glass

There was some damage to the glass. The windscreen had a couple of chips and somebody had thrown a brick at the rear near-side window and there was now a perfect outline of the projectile scuffed into the glass (see photo below).

Although chip repair in glass is something we can do at New Again, on this occasion we took the car to CCS windscreens because there was some work, we weren't capable of doing. The afore mentioned side window needed replacing, and the windscreen was incorrectly fitted, which they were able to rectify.

Normally, if you have this kind of work that needs to be done, we will just refer you to the right people, and you can take the car there yourself. But obviously, in this case the customer was in another country, so we are quite happy to manage this as a project, making sure that each job is sub-contracted to the right people, that it's completed to our exacting standards and done within the schedule.

One of the good reasons we took the car to CCS Windscreens is that they know all about sun roofs, and the roof on this Rolls-Royce had gone rusty and needed repair.

This is not the kind of thing they normally do, or we normally do for that matter, but they were able to remove it for us so that we could take it to somebody who could.

Rust

I have to stress that rust is something we normally steer clear of. It's not something that can be dealt with a smart repair. To be rid of it, normally you need to cut out the bad metal, weld in new metal, and this is normally done at a body-shop/panel-beaters. In normal cases, if you came to us with a rust problem, we would refer you to a car body repair shop, and in this case, we would recommend a replacement sun-roof.

However, this car's new home is Majorca, where there is far less humidity. Normally, a repair of the kind we have undertaken might last a couple of years before the rust would start to come through again (which in our opinion means it's only a temporary repair, and so doesn't meet our standards), but in the warmer climate of the Mediterranean, we feel that this repair could last many more years.

As mentioned previously, we managed this car as a project, taking the role of project managers for some of the work we can't do ourselves. We refer many people to specialists, but often a customer will bring a car to us and ask us to arrange and manage the work. So CCS windscreens removed the sunroof, and while the car returned to New Again to have the dents removed and the leather recoloured, we took the roof off to be shot blasted to remove the rust.

First it was taken to Maldon Shot Blasting and Powder Coating, who used a wet technique to blast the rust off and get back to the bare metal. This was actually a very delicate operation, the process causes huge amounts of friction, which causes heat which can warp and permanently damage the pressing. Unfortunately, Shot blasting wasn't quite enough to remove all the rust, and we were referred on to A1 Sandblasting who... blasted it with sand!

So, the sun roof was prepared and ready to be sent to Kraftwork which is our favourite body shop for this kind of work. However, it would have to wait because Davide was on holiday in Greece and would only return the two days before the car was due to go back to Majorca.

This is why we went to so much trouble to get it prepared and ready for painting. Normally, he would do all the preparation, but as things stood, we had a short window of time to get him to match the colour, paint it and return it to us so that we could get the car and roof back to CCS Windscreens, so they could reunite them.

Having had very little sleep, Davide arrived at New Again practically straight from the airport. He took the prepped roof, and also took the petrol cap as something for him to match the colour against. He got the finished Sunroof back in record time (above) and we were able to have it refitted on schedule.

So to sum up, CCS Windscreens removed it and refitted it, Maldon Shotblasting and A1 Sandblasting removed the rust, Kraftwork repainted it, and we did the running around and organizing. Despite the number of people and time involved, it still worked out less than half the price of a replacement Sunroof painted and fitted at a dealership.

Leather Seat Recolouring

With just about any project we undertake, there is usually a 'main thing' that leads to the customer bringing the car to us, often it's the leather.

Left is the photo emailed to us by the customer of their leather. It all looked a little tired with creases and minor cracks, years of grime and discolouration. Fortunately, Rolls-Royce leather is second-to-none in quality, and despite any cracks, with proper preparation, will provide a good solid base for recolouring

There is a lot of work involved in recolouring the seats in a car like this. Because of the blue piping, each seat is done in two stages. Firstly, the blue piping with the centre section is masked, but only after the seat is cleaned in minute detail, and then prep'd to remove all the dead old colour. Once this is recoloured, the blue piping with the outer section will be masked.

As with many such things, a quality job depends on the preparation. One of the most important things to do is get the seats absolutely clean and free from grit and dust which tends to build up between the seat panels and piping, and it's cleaned to remove grease and any acidic human contamination! This can be a problem, as we touch leather with our bare skin, our perspiration gets into it which is acidic -- you can often see it on leather steering wheels. A few years ago, when it was fashionable, we often had to deal with contamination from hair gel, more recently, fake tan has been a problem.

Next the leather is sanded to provide a surface that the new colour can key to. As with painting bodywork, there is no point in removing the original colour if it is good and solid, it's best to leave it on as if forms a strong undercoat. However, there were a couple of areas where there were cracks and crazing in the coating. This really needs to be removed because over time these cracks will extend down into the actual leather, so on these areas it was sanded back all the way to the bare hide.

The next job is to mask out the seats ready for spraying. This is rather tedious work, but essential to get right and done with great care.

The colour is matched by eye, to any area that won't be re-coated, in this case, the leather on the glove compartment. Rolls-Royce actually has paint codes for their leather, but it is impossible to use a tin off the shelf to get a colour match. Over the years, the leather in the car changes colour, so this can only be used as a base to which tints are added... and in this case, Darrell actually started from scratch. This is a highly skilled job which takes patience and experience. Darrell will add tints of white, black, red and purple until he gets the correct hue. He will then brush a small area, and wait to see how it looks when dry before making any adjustments. Often he may adjust the formula as he goes because different areas of the car will have different exposure to the sun, meaning that door panels are slightly different colour to the seats.

Another factor is the degree of matting agent to use. Most cars these days have a satin finish, some may even be matt. But as we sit on them, they become shiny. Most leather conditioners, feeds and even some leather cleaners will make the leather more shiny than the original.

It was then left overnight to fully cure, then the masking could be removed and the seats re-masked up for stage two and another day of spraying. It needs to be left overnight in this instance because it needs to be tough enough to put the masking tape on. But in the case of most of the interiors we do, the leather is a single colour, and we can do the car within a day.

Because the leather is sat on, it needs to be hard wearing and a special hard-wearing and flexible pigment is used. It's the same brand as applied at the tanneries which supply to the major car manufacturers. As already mentioned, the prep is important, especially so for ensuring that the colour is hard-wearing. It also needs to be applied in multiple thin coats; otherwise it will 'skin', drying on the surface, but not drying underneath. On this particular car, the colour was first sponged on to the bare areas in two coats, and then a further five coats were sprayed on using a professional spray gun.

Finally, the pigment is brushed onto the piping by hand... a very steady hand! Obviously, a mistake or slip of the brush at this stage would be a disaster! Again, the colour for this was mixed by eye to the larger areas of blue detail on the dashboard.

Leather Steering Wheel and Door Panels

The door panels were also done, there was little wear on these and less discolouration, but it's especially important to get the handle clean and free of human contamination before recolouring can begin.

As already mentioned, the walnut trim had been sent away to Cooper Woodtrim for refurbishment, which is why they are missing in the photo above.

The rest of the detail was masked, and the door panel recoloured with a spray gun.

The steering wheel posed a new problem for us. It appears that the leather on the face had become loose and had obvious bubbles. It's quite likely that heat from direct sunlight had caused the leather to expand, and also soften the glue underneath that held it down flat.

We considered sending it to a trimmer to remove the leather and glue it back in place, but this is a sealed unit containing the airbag and the explosive devices which make it work... such things are best not to tampered with. However, we know that when leather gets wet and then dries, it contracts. So, we carefully made it damp and then heated it several times and luckily, it shrunk back. There are no guarantees that this will last, but it's certainly worth a go when you consider what it would cost for a fitted replacement unit from a dealership.

Steering wheels can be really tricky. They are very high wear areas and often the colour can wear through fairly quickly and they are exposed to lots of sun and heat which makes them dry. You can find that your hands are in contact with dry bare leather, the moisture from your hands along with any dirt and grime will become absorbed. This transfer tends to be acidic and will eat away at the leather. So special preparation is used when doing steering wheels, they are very carefully cleaned and keyed.

Once again, Darrell mixed the pigments by eye to an exact match, this time using a special extra hard-wearing formula. Apart from that, the process was exactly as described before.

All in all, it took Darrell around 30 hours over 4 days to complete the front and partial back seats, door panels and steering wheel.

Darrell himself says that it was one of the best jobs he has ever done, and the results were remarkable.

Although we take great pains not to 'over promise' what we are capable of, this was one of those occasions where the leather came up pretty much like brand new.

Paintless Dent Repair

We inspected the car for bodywork damage. There are a couple of areas that have been scuffed, scraped and even gouged. We didn't think we could repair all the damage on the car with smart repairs and that they warranted full car body shop repair.

Unfortunately, there was no time to do this on this visit to England, so this will be done when the car returns in the winter. But we were able to do the dents on the panels that won't be repainted.

The car was inspected, and the dents marked out with tape for Chris to do. There were 22 minor dents in total, of which we were able to do about 14, the rest couldn't be done because of lack of access. As dents are pushed out from behind, sometimes we are hindered by double-skins or strengthening structures behind the panels.

While we were inspecting the vehicle, it was noticed that there was a dent in the hub cap, and it was marked for Chris to do. Unfortunately, he didn't notice the marker and so didn't do the dent. Doing dents on wheels is not something he often sees, so he wasn't looking, in fact, it's very rare to see hub caps on a car these days. But he may still have more dents to do anyway when the car comes back again.

Work in Progress

So by the end of this first phase, the leather looked great, the wheels looked great, the sun roof was sorted out, and once given a coat of wax, the car looked good enough to turn heads.

There are some other bits of body work that need to be done, including a scuff on the bumper, and some interior details that needs attention. There is a scuff on the steering column, and the headlining is stained, probably by water from the leaky sun roof or windscreen.

Although the car looks shiny in the photos, this is down to the wax -- on closer inspection the paintwork is covered in swirl marks or 'spider webs'. Once the bodywork is completed, we will be able to carry out paintwork correction on the car, machine polishing it to a high shine.

If you have an older car that you think could benefit from modern car restoration, please get in touch, so we can discuss your needs.

by Danny Argent

technical writer, education and training.

Related Blogs

Here are some more of our latest #ModernCarRestoration blogs

Modern Car Restoration: The Smart Alternative to Buying New

If your car is starting to look a little tired, you might be wondering whether it’s time to replace it. But what if there was a smarter, more cost-effective option?

Read ArticleThe Smart Way to Get a New Car Without the New Car Price

We all know the allure of a shiny new car. The smell, the pristine interior, the flawless paintwork—it’s enough to make anyone consider trading in their current car.

Read ArticleHow to make a car shine like glass

Ever wondered how you get a really shiny car? There are plenty of products on the market which promise a glossy wet look, but the real secret to a mirror finish is polishing.

Read ArticleWet Sanding

Wet Sanding is the method we use to remove light scratches and blemishes, evening out the paint so it can then be machine polished.

Read ArticleHow much does it cost to polish a car?

If you are thinking of having your car professionally machine polished in the UK, you might be confused about the pricing.

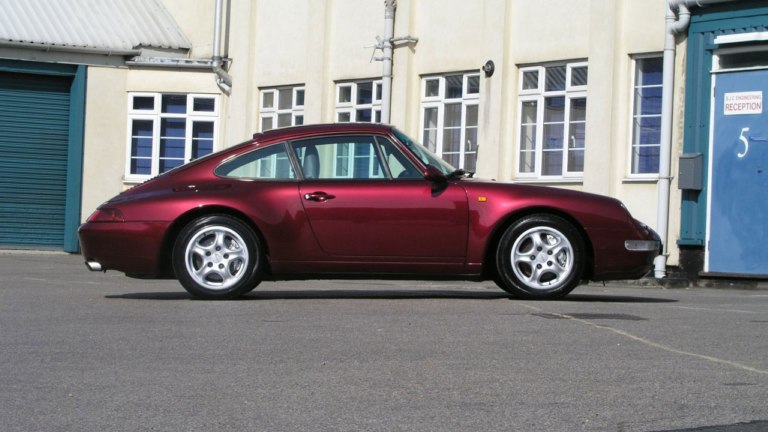

Read ArticlePorsche Detailing / Restoration 2005-2019

This Porsche Carrera came to us for Modern Car Restoration, it had some rust on the rear end and required some quite serious bodywork. But that's not what's interesting about this Porsche!

Read ArticleAston-Martin Vantage Modern Car Restoration

A behind the scenes look at the kind of work we do at New Again in Modern Car Restoration. This car has been sitting in storage for five years and is in need of some attention.

Read ArticleHow is sports car restoration beneficial?

If you are looking for a company specialising in sports car restoration Chelmsford has the perfect option. New Again has been excelling in this area and various others for years. We have some of the most impressive facilities and the best people to ensure ...

Read ArticleA word of caution about wear

It's true that New Again can repair all kinds of minor damage and wear, putting it right and making a car look much fresher and newer. But did you ever stop to think what the wear on a car tells you?

Read Article

Can We Help You?

"We can offer specialist advice on the best car service to suit your requirements"

When bringing your car to New Again, we often ask you to explain exactly the reason for having your car Protected, Valeted or Repaired. Once we understand exactly what it is you are trying to achieve, we will appraise your vehicle using our detailed appraisal check-sheet allowing us to identify areas of concern and tailor specific services that match your requirements and budget.

If you are not sure what service you need and would like to speak to one of our technicians, simply request a callback by filling in the form on our contact page.

Share this blog