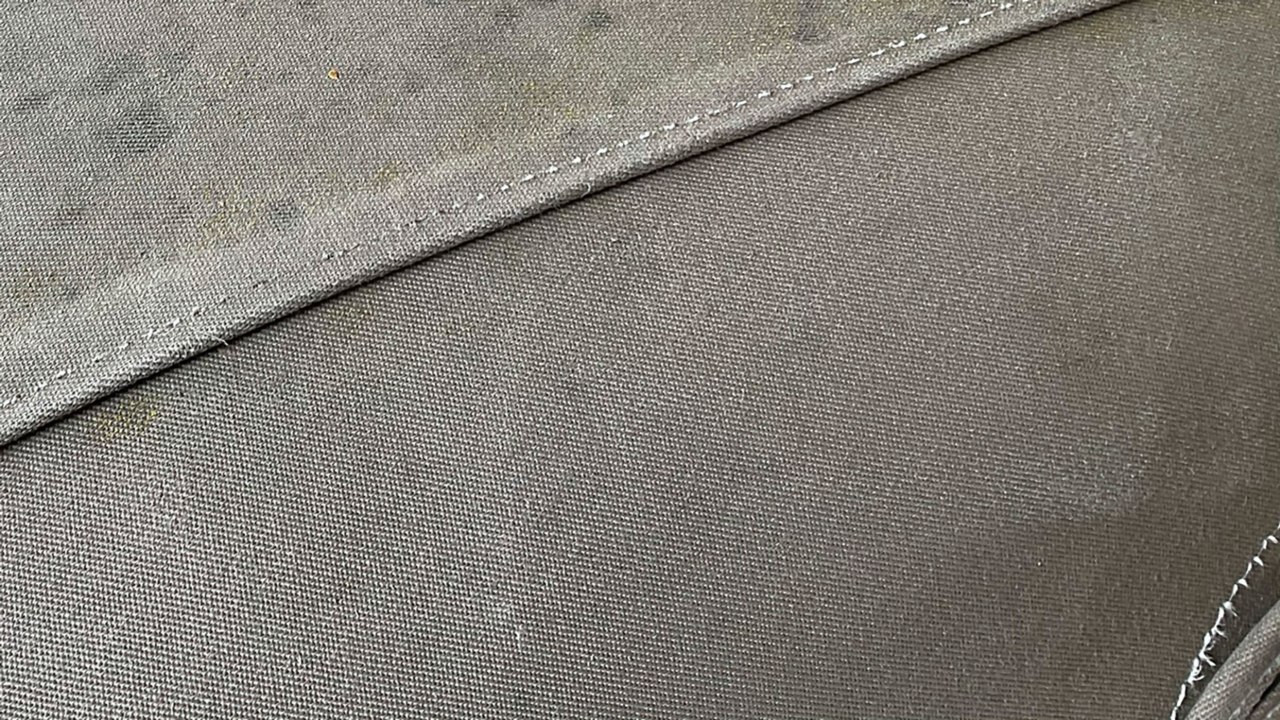

Stiching

Quick answer: Stitching is the thread and sewn seams that hold the panels of a convertible hood or fabric roof together. If the stitching rots, frays or splits, the roof weakens, can start leaking and will often need repair or retrimming.

Your roof is both glued and stitched together, making it very strong, however, some exposed stitching can be delicate and prone to rot if your hood is not properly maintained. Thankfully, they are not the only thing holding your roof together.

Great care should be taken when cleaning your hood around areas of stitching. While it is safe to use a brush on the main fabric parts of your roof, areas of stitching could be damaged.

What it means

Stitching is the sewn thread that holds the panels of a convertible hood or fabric roof together. The outer skin, inner lining, pockets, tension straps and detailing are all joined with rows of stitching that run along seams and edges. On older cars and well used roofs, the thread itself can become the weak point: it can fade, rot, break or pull through the material even when the fabric still looks reasonable.

Why it matters

- Keeps the hood in one piece: Sound stitching keeps the roof tight over the frame so it holds its shape and does not flap or sag.

- Critical for keeping water out: Split seams and missing stitches can open up little channels where water creeps through, leading to drips, damp trim and misty windows.

- Affects strength and safety: On some roofs, stitching also secures tension straps and pockets that control how the hood folds. If these fail, the mechanism can strain or fold awkwardly.

- Key factor in whether repair is viable: A roof with generally good fabric but failing stitching may be a candidate for specialist re-stitching. If both fabric and stitching are tired, a new hood is often more sensible.

Where you’ll see it

You will see stitching mentioned on inspection reports, water leak assessments and trimming or hood replacement quotes. Common comments include stitching perished at rear corners, hood stitching gone along seams or stitching needs attention around rear screen. Detailers may also note stitching condition when advising on cleaning and proofing, as aggressive methods can accelerate wear on already weak seams.

Context

Stitching is one part of the wider hood system, along with the fabric or vinyl, frame, seals, gutters and drains. On modern mohair and fabric roofs the thread is usually synthetic and UV-resistant, but age, sunlight, chemicals and constant folding still take a toll. Classic duck hooding and some older vinyl roofs may use more traditional threads that are even more prone to rot if left damp. When chasing leaks, it is important to distinguish between water seeping directly through tired fabric and water tracking along or through failed stitching at seams, as the repair approach is different.

Common mistakes

- Assuming leaks near seams always mean the fabric has failed, when the real culprit is rotten stitching that now lets water creep through the needle holes.

- Scrubbing aggressively across stitch lines with stiff brushes or strong TFR, which can rough up the thread and shorten its life.

- Leaving clearly perished stitching until whole seams open up, turning a simple re-stitching job into a full hood replacement.

- Trying DIY re-stitching with unsuitable thread that is not UV or weather resistant, leading to a patchwork of weak repairs that soon fail again.

Written by Danny Argent. Last updated 01/12/2025 17:11